5 Steps to Modernising Agri-Business Operations with ERP (Odoo Guide for Africa, Middle East & UK)

Discover 5 steps to modernise agri-business operations with ERP. Learn how Odoo helps farms in Africa, the Middle East & UK replace manual processes.

Manual spreadsheets and paper forms might have run your farm for years, but they could be holding your business back. In today’s economy, companies can lose up to 30% of revenue due to inefficiencies from outdated systems and manual processes.

This is especially true in agriculture, where many businesses in the Middle East, Africa, and the UK still manage inventory, orders, and finances via spreadsheets or pen-and-paper.

In fact, 68% of African SMEs (including agribusinesses) rely primarily on manual processes and spreadsheets, with employees wasting up to 40% of their time on repetitive tasks. Manual data entry isn’t just slow – it’s error-prone (errors occur at rates hundreds of times higher than with automation) and it stifles growth (businesses using manual methods grow 60% slower than those that automate).

The solution? Modernise your operations with an Enterprise Resource Planning (ERP) system.

ERP software (like Odoo, a popular open-source ERP) integrates all your key business functions – from field and inventory management to sales and accounting- into one seamless platform. This integration helps you move away from manual workflows by centralising data, automating routine tasks, and providing real-time insights. The result is fewer costly errors, faster processes, and better decision-making.

For example, one UK food distributor that adopted an industry-specific ERP said, “the solution has transformed our business. It has helped us replace our manual processes and provides us with accurate live data... making our process far more efficient and our team more productive.”

Across Africa and the Middle East, too, companies are embracing ERPs as a game-changer: the Middle East & Africa ERP software market is projected to nearly double from about $5.4 billion in 2024 to $10.2 billion by 2032, fueled by organizations looking to streamline operations and go paperless in line with government digital initiatives.

In this post, we’ll walk through 5 practical steps to modernise your agricultural operations with an ERP. You’ll learn how to assess your current processes, implement an ERP solution in a structured way, and see real-world examples – especially highlighting Odoo – of how agri-businesses in Africa, the Middle East, and the UK have ditched manual processes for integrated, efficient systems.

Let’s get started on the path from spreadsheet chaos to streamlined success!

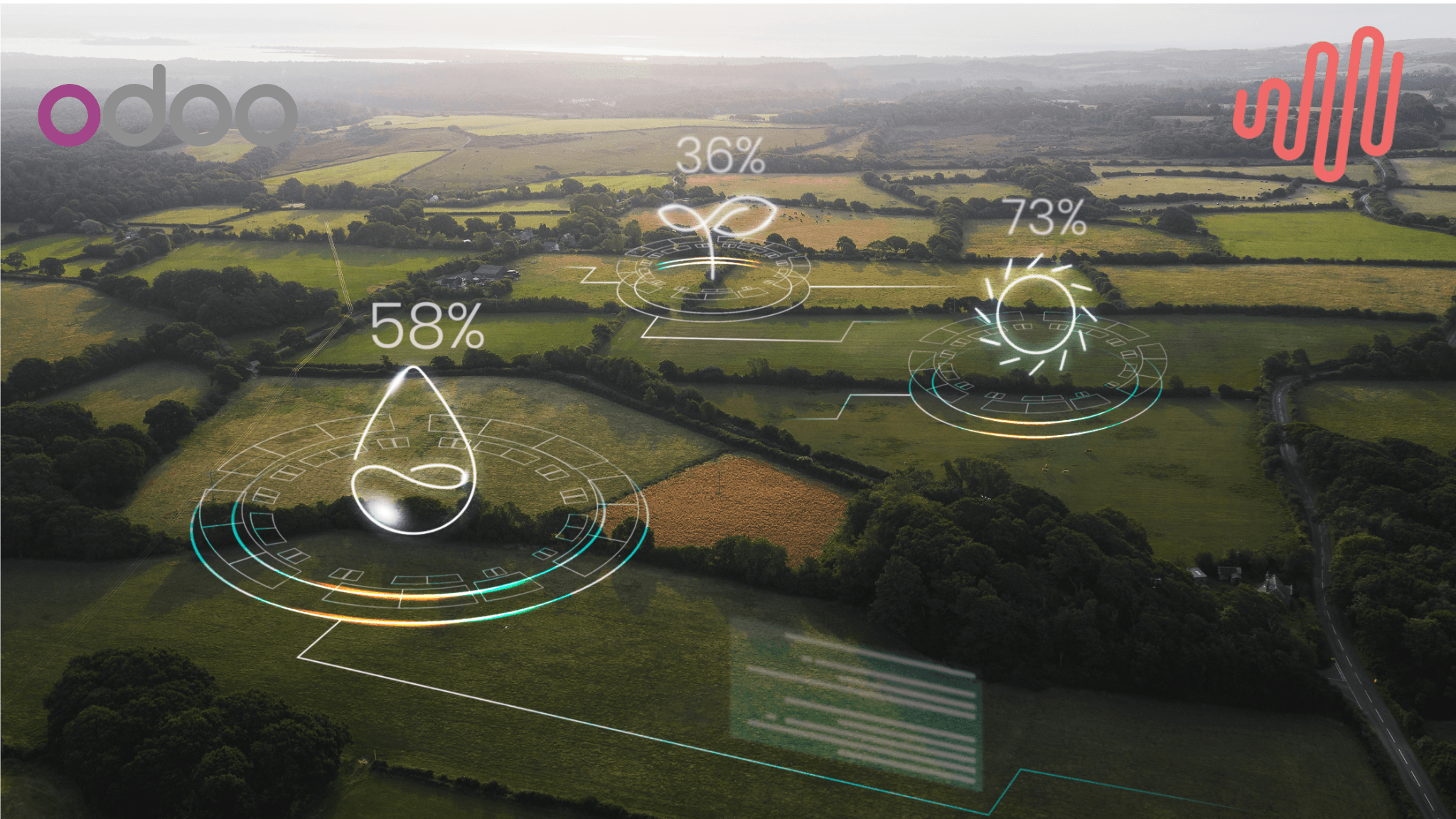

A modern tomato farm using digital tools: After implementing Odoo ERP, a European farm achieved a 40% boost in efficiency and cut post-harvest losses by 60% by replacing manual tracking with real-time data via tablets and integrated apps.

Step 1: Evaluate Your Current Manual Processes and Pain Points

The first step towards modernising is to take a hard look at your current operations. Map out how you’re doing things today: How are you tracking planting schedules, inventory of seeds and fertilizers, crop yields, sales orders, or equipment maintenance?

If the answer involves a patchwork of Excel sheets, paper logs, and people’s memories, it’s time to document those processes and identify the biggest pain points.

Common challenges in traditional farm operations include:

- Data silos and duplication: You might use one spreadsheet for stock, another for sales, and none of them talk to each other. Information gets duplicated or lost. This fragmented approach makes it hard to get the full picture of your business.

- Manual data entry errors: Typing numbers by hand late at night after a long day in the field is a recipe for mistakes. Manual tracking is prone to human error, leading to inaccurate data that can skew your decisions. (Ever missed a delivery because someone mis-copied an order date?)

- No real-time visibility: If you’re updating records only at the end of the week, you never have up-to-date information. Without real-time data, you react too slowly – for instance, not realizing a pesticide is nearly out of stock until it’s too late.

- Inefficient planning & scheduling: Farms that lack proper tools struggle to plan crop cycles and labor needs efficiently. This can lead to overplanting some fields and under-utilising others, or having workers idle in one area while another field needs urgent attention.

- Labor and process inefficiencies: When task assignments or harvest logs are done on paper, it’s easy for communication to slip. Many farms suffer from labor inefficiency simply because there’s no system to schedule and track work in real time. Seasonal workers might not know where to focus, or multiple people may be doing the same task.

- Lack of cost and performance insights: Perhaps the biggest hidden pain is not truly knowing your costs, margins, or yield performance until long after the season. A manual system makes it hard to analyze profitability by crop or field. You might be losing money on a product and not realize until the annual accounts are done.

These pain points have a real financial impact. In one case, a European tomato farm’s operations were “heavily manual, leading to wastage of time, food spoilage, and missed sales opportunities”. They had no central system for planting schedules or harvest tracking, suffered labor inefficiencies from disorganized task assignment, and lacked visibility into costs and yields. The result was serious revenue loss. Similarly, in the UAE, a large agro-livestock company (EKTIFA) found that running on Excel sheets meant no real-time inventory or production control, no integration between feed, sales, and livestock data, and difficulty scaling to meet demand. These examples might sound familiar to you – and they underscore why modernising is critical.

Action: Make a list of all the manual or semi-manual processes in your operations. Discuss with your team the frustrations you’re experiencing (e.g., “it takes us days to consolidate farm reports from all regions” or “we often run out of stock because we don’t have timely alerts”).

Quantify the impact if you can – how many hours are wasted, how often errors occur, or how much produce is lost due to these inefficiencies. This baseline assessment will not only justify the need for an ERP but also guide you in what to focus on when implementing one.

Step 2: Set Clear Goals and Choose the Right ERP Solution (Why Odoo Shines)

With your pain points in hand, define what “modernisation” means for your farm or agri-business. Set clear goals that you want an ERP to achieve. For example: “Reduce post-harvest fruit waste to under 5%,” “Cut manual data entry work by half,” “Get real-time visibility of inventory and sales,” or “Improve traceability to meet export standards.”

Having specific objectives will help you evaluate and choose the right ERP system – one that best fits your needs and budget.

When it comes to choosing an ERP, you’ll encounter options from big-name corporate systems to farm-specific software. Here, we’ll focus on Odoo as a compelling choice, especially for agricultural businesses in the Middle East, Africa, and the UK:

- Cost-Effective for all sizes: Unlike some enterprise systems that cost a fortune, Odoo’s open-source model makes it very affordable for small and medium businesses. You can start with the Community edition (which has no license fee) or opt for the paid Enterprise version for extra features – either way, you’re not breaking the bank.

This is crucial for agri-businesses, which often operate on thin margins. Odoo delivers enterprise-level functionalitywithout an enterprise price tag.

- Modular and customizable: Agriculture is a diverse industry – a dairy farm’s needs differ from a crop exporter’s. Odoo’s modular structure lets you pick and choose the apps you need (e.g., Inventory, Manufacturing, Accounting, CRM, Purchasing, etc.), and you can customize workflows to suit your operations.

This flexibility means the system can be tailored to your specific processes: whether it’s managing field planting schedules or tracking livestock health records, you can configure Odoo to handle it. You won’t be stuck with a one-size-fits-all process; you build the ERP around your business.

- Integrated and user-friendly: All the Odoo modules talk to each other seamlessly, sharing data in one database. For instance, when you record a harvest in the inventory app, it can automatically update your accounting and create availability for sales – no double entry.

Despite its power, Odoo’s interface is relatively friendly and easy to use (it’s designed to be both “very easy to use and fully integrated”odoo.com). This is a significant advantage when integrating teams that may be new to ERPs, as a gentle learning curve facilitates a smoother transition away from spreadsheets.

- Scalable and cloud-ready: If you plan to grow (more hectares, new product lines, expansion to new markets), your ERP should grow with you. Odoo can scale from a few users to thousands. It can be deployed on your own servers or in the cloud, giving you flexibility.

Cloud deployment in particular offers Middle Eastern and African businesses the ability to scale quickly without worrying about maintaining servers. And if you have multiple sites or remote fields, cloud access means everyone can connect to the system in real time.

- Localization and regional support: For businesses in specific regions, the software must handle local requirements. Odoo has strong support for localization – for example, it supports multiple languages (including Arabic) and region-specific accounting rules (VAT, etc.) out of the box.

There’s also a growing network of Odoo partners and experts in Africa and the Middle East, meaning you can find local support for implementation. (Notably, Odoo S.A. itself has expanded its footprint in Africa, e.g., helping the Egyptian government with e-invoicing, and is listed among the top ERP providers in the MEA region, which speaks to its credibility and adoption.)

Of course, the “right ERP” is the one that best meets your goals. When evaluating others, look for those who have proven agricultural modules (for crop/stock management), can integrate all areas of your business, and have successful case studies in similar businesses. It’s worth checking references or case studies from any vendor.

For instance, if you’re considering Odoo, you’ll find many agri-business success stories: East Africa Fruits in Tanzania replaced its legacy systems with Odoo in 2023 to connect smallholder farmers better to markets, and a UN-led project in Liberia used Odoo to build a platform for women farmers to buy inputs and sell produce via mobile app (showing Odoo’s versatility, from e-commerce to SMS integration in remote areas). Knowing that similar organizations have succeeded with an ERP gives you confidence in your choice.

Action: Research 2–3 ERP options and list how they meet your requirements (and your budget). If possible, get a demo or trial – Odoo, for example, offers a free trial and has an active community, so you can even test the waters with a demo database. Involve key team members in the selection process, especially those who will be end-users, to get their feedback on usability.

Step 3: Plan a Phased Implementation and Migrate Your Data

Embarking on an ERP implementation can feel daunting, but with a good plan, you can roll it out in manageable steps. Rather than trying to switch everything over in one go (which can overwhelm your team and risk business disruption), it often works best to implement in phases.

How to implement in phases:

- Start with critical modules: Identify a few high-impact areas from Step 1 and tackle those first. Many agri-businesses begin with modules like inventory (to get stock and supply chain under control) and Accounting (to replace manual ledgers or separate software).

You might also include Sales/CRM if you deal with lots of orders, or Production/Manufacturing if you process food products. Focus on areas that will immediately eliminate a lot of manual work.

For example, automating inventory tracking can quickly reduce wastage – Silent Infotech (an Odoo partner) helped a tomato farm in Southern Europe implement Odoo’s inventory module to track seeds, fertilizers, tools, and harvested tomatoes in real time, ensuring timely restocking and cutting spoilage significantly.

- Migrate your data carefully: One of the most important tasks is moving your existing data (customer lists, product info, stock levels, financial balances, etc.) into the ERP. Clean up the data first – remove duplicates, correct errors – so you’re not importing garbage.

This might be the first time all your disparate spreadsheets are consolidated, which is a huge benefit on its own. Take it step by step: perhaps import master data (products, vendors, customers) first, then opening balances, etc. Most ERP systems provide import tools (CSV/Excel import) to make this easier. It’s worth testing the migration on a sandbox system to catch any issues.

- Configure and customize to fit your processes: During implementation, you or your implementation partner will configure the ERP to match your workflows. This could mean setting up your chart of accounts for farming, customizing fields (e.g., adding “Field ID” to inventory lots to track which farm field a crop came from), or even integrating third-party tools.

The key is not to over-customize to the point of complexity, but to align the system with your real needs. Odoo’s flexibility is handy here – you can, for instance, add an Odoo Survey module for field inspections or integrate a weather API.

In one project, developers integrated real-time weather data and Google Maps into Odoo for a farming operation, so that field officers could monitor rainfall by plot and plan interventions with optimized routes. Such integrations might be phase 2 or 3 of your rollout – they’re not core ERP features, but show that as your needs grow, your ERP can accommodate them.

- Test and iterate: Before going live, do trial runs. Enter sample transactions and simulate a “day in the life” of your business in the new system to ensure everything works as expected. Fix any bugs or mismatches in the process.

It’s cheaper and easier to adjust configurations now than after you’ve got live data flying around. Consider running the new ERP in parallel with your old system for a short period (if feasible) to validate outcomes. For example, record one week’s farm sales in both Excel and the ERP, and compare the results – this will help build trust in the ERP’s accuracy.

- Go live with a subset, then expand: Once you’re comfortable, proceed with the first phase modules. Keep a close eye on the process and have a support plan (who do users call if something is confusing?).

After successfully running the essentials, you can gradually expand to additional modules or features in subsequent phases. For instance, after stabilizing inventory and sales, you might introduce a Maintenance module for your farm equipment, or an HR module for payroll of farm workers. Each phase brings more of your operations into the fold of the ERP.

Real-world implementations validate this phased approach. The tomato farm case is a great example: they didn’t turn on everything at once. They first set up a calendar dashboard for crop planning and scheduling, then added Odoo apps one by one – inventory management for inputs/outputs, accounting for tracking costs and subsidies, timesheets for field labor management, and finally sales & distribution automation (connecting orders from buyers to their system for quick invoicing).

This stepwise rollout meant the farm could adapt gradually. The payoff was huge: post-ERP, they saw a 40% increase in operational efficiency and a 60% reduction in post-harvest losses, along with lower input costs and higher staff productivity. Incremental implementation, done right, delivered transformative results.

Action: Develop an implementation roadmap. Decide which process or module to tackle first, second, etc., and set tentative timelines. If you’re using a partner or consultant (which can be very helpful for Odoo or any ERP), work with them to define these phases. Ensure data migration and testing are explicitly in the plan. Remember to include key users in testing – their buy-in and familiarity will ensure a smoother go-live.

Step 4: Train Your Team and Embrace Change Management

Even the best software won’t deliver results if your people don’t use it effectively. Agriculture businesses often have staff who’ve “always done it this way” – convincing them to trust a new digital system is arguably the hardest part of modernisation. That’s why training and change management deserve their own step.

Keys to success in this step:

- Get buy-in with a clear vision: Explain to your team why the change is happening. For instance, highlight that by eliminating tedious manual chores, they’ll have more time for high-value work (and less paperwork on Fridays!). If you have data from Step 1 (like error rates or hours wasted), share the reality:

e.g., “We spend 15 hours a week just merging spreadsheets – wouldn’t you rather use that time to improve the harvest process or market our products?” Enlist champions, such as a farm manager excited about technology, to advocate for the ERP.

- Provide thorough training by scheduling sessions around the go-live date. With Odoo, many users find the interface intuitive, but don’t assume it’s all self-explanatory. Offer hands-on workshops where team members practice tasks they’ll need to do, such as entering a new sale order, recording harvested quantities, and checking a report.

Use your actual data in a test system to make it realistic. Also, leverage available resources – Odoo, for example, has ample documentation and tutorials online, and your implementation partner might provide user manuals or help videos. Make sure everyone knows who to ask for help in the early days.

- Highlight quick wins: People resist change less when they see immediate benefits. So celebrate the first small win. For example, after training your warehouse or store team on using Odoo’s tablet picking app (if you have one), they might have processed orders faster or with fewer mistakes – be sure to highlight this!

- Goosemoor Foodservice, a UK company, noted that after implementing their ERP and training staff on the new picking workflow, the team became much more efficient and productive in order fulfillment. Share such stories or internal metrics (“we shipped 20% more orders this week with the same staff, thanks to the new system!”) to reinforce positive feelings about the change.

- Adapt processes (and be patient): Introducing an ERP might require some process changes to align with best practices. During training, gather feedback – perhaps the way a screen is laid out could be improved, or a certain step in the software is confusing.

You might need to tweak the ERP configuration or provide a workaround. Be patient as everyone adjusts. It’s normal to hit a few bumps early on. Encourage a culture where employees report issues or suggest improvements rather than reverting to old habits quietly.

For example, if field agents find it hard to enter data on a mobile device on-site, maybe the process can be adjusted so they take quick notes and input later, or you provide a better rugged tablet – listen and adapt.

- Monitor usage: In the weeks after go-live, keep an eye on whether the team is actually using the ERP for the intended tasks. If you see, say, purchases still being ordered outside the system or someone maintaining a parallel spreadsheet “just in case,” address it. Sometimes additional coaching or simply turning off the old method (e.g., turning off the old Excel template) might be needed to reinforce the new way.

Remember, the goal is to make your staff’s work easier and more effective, not just to impose technology. When done right, your people will eventually wonder how they lived without the ERP.

One farming operation reported a 35% increase in staff productivity during peak season after they fully adopted the new ERP processes– the team was able to handle more workload with less stress because the system took care of so many formerly manual tasks. That kind of improvement is only possible with a workforce that’s on board and well-trained.

Action: Develop a training plan. Who needs to learn what? Create a schedule for training sessions (and don’t make them one marathon day – shorter, focused sessions tend to be better).

Also, plan for go-live support: maybe assign a tech-savvy person or an external consultant to be “on call” on the first days to answer questions.

Communicate early and often about the upcoming changes so no one is caught by surprise. Consider a bit of change management marketing: e.g., put up a poster in the farm office, “Our New System is Coming – Get ready to ditch the paperwork!” to build awareness in a friendly way.

Step 5: Monitor the Results and Continuously Optimize (Scale Up Your ERP)

Congratulations – you’ve implemented your ERP and your team is using it. But modernising operations is an ongoing journey, not a one-time project. The final step involves monitoring your new system’s performance and continuously improving both software usage and your business processes. Additionally, as your business grows or changes, you’ll want to scale up your ERP capabilities.

Here’s how to make the most of your modernised operations:

- Track key metrics and compare to your goals: Remember those goals you set in Step 2 (like reducing waste, improving efficiency)? Now you can measure progress. Use your ERP’s reporting and dashboard features to keep an eye on relevant metrics.

For example, Odoo and most ERPs allow you to create dashboards for things like “Low-Stock Items,” “Orders Pending Delivery,” or “Farm Yield vs Target.” Goosemoor’s team mentioned that after implementing their system, they gained instant live snapshot views of operations – from low-stock alerts to order fulfillment status – via personalized dashboards and KPIs. This kind of visibility is powerful.

Schedule a review (monthly or quarterly) of key performance indicators now that you’re on ERP. Are you seeing the expected improvements? If not, why? Perhaps additional training is necessary, or the ERP process could be adjusted.

- Optimize processes using data insights: One significant advantage of an ERP is that it enables you to collect clean, centralized data across your operation. Use that! Perhaps you discover that one crop has consistently lower margins – you could investigate if it’s an issue of cost or price.

Or you might notice that deliveries on Tuesdays are always delayed – maybe because Monday harvesting is too tight; you can tweak the schedule. ERP reports and even AI-driven analytics can reveal bottlenecks or opportunities that were hidden before.

Many businesses using Odoo find that the detailed reports and analytics give them actionable insights for decision-making– for instance, identifying exactly which farm locations are most profitable or which customers are slowest to pay, and then taking action accordingly.

- Expand your ERP’s footprint when ready: After the initial modules are running smoothly, consider what else you can bring into the system to eliminate manual work further. The beauty of a system like Odoo is that you can turn on additional modules as needed.

Perhaps next season you want to implement the Quality module to track crop quality inspections, or integrate an IoT device to update storage temperatures in your inventory records automatically. If you started with on-premise and you’re ready to ease maintenance, you might migrate to cloud hosting.

Or maybe you begin to use the mobile app features more for on-field data entry by agronomists. Keep an eye on new releases and features; Odoo, for instance, updates annually and often introduces apps or improvements that could benefit agriculture (like better fleet management for farm vehicles or improved forecasting tools).

The goal is to leverage the ERP to drive innovation in your operations continuously – you’ve built a digital foundation, now build on it.

- Stay scalable and modular: As your business grows (with more farms, new products, or expansion into new regions), ensure your ERP scales accordingly. This might mean adding more user licenses, increasing server capacity, or optimising your database. It could also mean refining user roles and permissions as your staff grows.

Because you chose a flexible ERP, scaling should be relatively straightforward – but it’s worth planning. Many companies in growth markets choose Odoo for its scalability; it’s not uncommon to see a small agribusiness grow with Odoo from 5 users to 50+ as they expand, simply by activating more apps and users without re-implementing a whole new system.

In the Middle East, companies have found that Odoo’s cloud-based approach lets them “scale operations quickly without worrying about server infrastructure, which is ideal when you need to expand to new sites or branches quickly.

- Keep up with maintenance and support: An ERP is like a farm vehicle – it needs regular check-ups. Ensure you have a maintenance plan: apply updates or patches (especially for security) and back up your data routinely.

If using Odoo Enterprise or a partner’s services, stay in contact for any support issues. Periodically review if there are features you aren’t using yet that could help – sometimes businesses realize they’re not taking advantage of something they’re already paying for, like an automated workflow that could save even more time.

A great example of continuous improvement comes from a large organic farm in the UAE. After implementing a cloud ERP, they not only achieved 100% paperless procurementand 30% better inventory accuracy, but they also continued to drive improvements. They integrated field sales mobile apps for real-time order and delivery tracking, and adopted AI-powered dashboards for forecasting.

The result was a highly agile operation that could scale to thousands of animals and multiple product lines, all while maintaining full visibility and control. The lesson is that ERP modernisation isn’t a one-and-done; it’s a cycle of improvement.

With each refinement, you squeeze more value from the system and more efficiency from your processes.

Action: After a few months on the new system, set up an “optimization meeting” with your team. Discuss what’s working well and what could be better. Perhaps the sales team needs a faster way to input orders from the field; in that case, you could deploy the Odoo mobile app for them.

Or the farm manager might request a custom report on fertilizer usage per field – you can develop that. Make a continuous improvement plan. Additionally, stay informed about ERP updates or new modules (subscribe to newsletters or user groups).

Continuous learning will help you take advantage of everything your ERP can offer.

Conclusion: Reaping the Rewards of a Modern ERP-Driven Operation

Modernising your agricultural business with an ERP is a journey that pays off richly. By following these five steps – assessing your manual pains, choosing the right ERP (like Odoo) that fits your needs, implementing methodically, training your people, and continually improving – you pave the way to a more efficient, agile, and scalable operation.

No more losing sleep over disjointed spreadsheets or surprise stockouts; instead, you gain confidence from real-time data and integrated workflows.

The case studies we touched on demonstrate the real impact: a tomato farm turned around its fortunes with a 40% efficiency boost and drastically reduced waste by moving off manual processes.

An African foundation digitized 10,000+ farmer records and achieved real-time reporting thanks to Odoo, making their programs more transparent and effective. Businesses that once struggled with legacy systems or Excel chaos are now leveraging ERPs to cut costs by 20–30%, improve decision-making speed, and even innovate new services.

It’s telling that 95% of organizations report improved processes after implementing an ERP – the odds are in your favor.

For agricultural enterprises in the Middle East and Africa, the timing is ideal. Governments and markets are encouraging digital transformation (e.g., paperless initiatives and e-invoicing requirements), and ERP technology has never been more accessible.

Odoo in particular stands out as a strong fit for agri-businesses in these regions because of its affordability, modular flexibility, and local support.

Whether you’re a family farm in the UK looking to streamline operations, or a growing agribusiness in Kenya aiming to connect small farmers to big markets, Odoo can scale to your needs without the traditional ERP sticker shock. It’s no surprise that over 50,000 companies run Odoo to grow their business– including many in agriculture.

In the end, modernising with an ERP is about moving away from the drudgery of manual processes and unlocking time and insights to focus on what you do best: farming and growing your business. It’s about knowing, at any given moment, how your operation is performing and being able to react quickly to challenges like weather, pests, or market changes.

It’s also about freeing up your team from mundane tasks so they can concentrate on innovation and improvement. As one African tech firm aptly put it, “automation isn’t just a cost-saver; it’s a competitive edge”.

By embracing ERP, you’re effectively giving your agri-business that competitive edge – the ability to do more with less, to make smarter decisions, and to ensure every seed, drop of water, and shilling or pound invested yields the best possible return.

Ready to modernise? With these five steps as your guide, you can confidently lead your agri-business into a new era of efficiency.

Say goodbye to spreadsheet headaches and hello to a smoother, smarter way of operating. The farms of the future are connected, data-driven, and agile – and with the right ERP, yours will be too. Happy modernising!

0 comments

newest